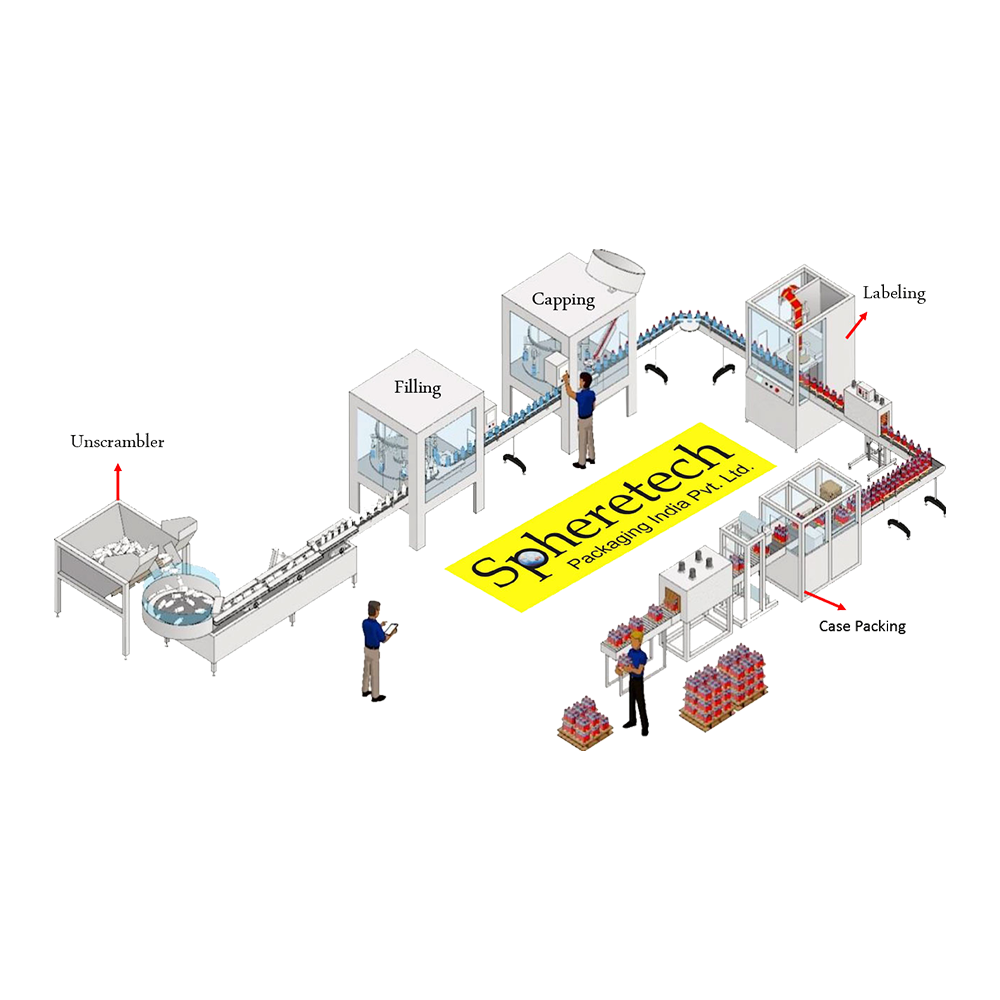

Spheretech provides comprehensive packaging line solutions for bottle filling, seamlessly integrating each stage from bottle feeding to case packing. Below is an overview of the steps involved in this integration, highlighting the equipment and processes used to ensure efficiency, accuracy, and product safety.

- Bottle Feeding Objective : To feed empty bottles into the production line in a controlled and consistent manner.

- Bottle Unscramblers : Orient and feed bottles into the filling line, handling different sizes and shapes to ensure correct orientation. Options include Rotary Unscramblers, Linear Unscramblers, and Robotic Unscramblers.

- Conveyors : Transport bottles from the unscrambler or directly from blowing machine to the filling machine, maintaining a steady flow and preventing jams.

- Filling Objective : To fill bottles with the product accurately and efficiently.

- Filling Machines : Depending on the product, Spheretech offers various types of filling machines such as gravity weight fillers, piston fillers, and pump fillers to ensure precise fill levels, minimizing wastage and ensuring consistency.

- Nozzles : Critical components controlling the product flow into bottles, customized for different product viscosities.

- Capping Objective : To securely seal filled bottles with caps

- Capping Machines : Place and secure caps onto bottles. Options include screw cappers, snap cappers, and rotary cappers, each suited for different cap types and production speeds.

- Cap Feeders : Sort and deliver caps to the capping machine, ensuring a continuous supply.

- Labelling Objective : To apply labels for branding, information, and regulatory compliance.

- Labelling Machines : Apply labels to bottles with precision, ensuring correct positioning and adherence. Options include pressure-sensitive labelers, shrink sleeve labelers, and wrap-around labelers

- Printers : Add date codes, batch numbers, and other variable information to labels or directly onto bottles.

- Inspection Objective : To ensure quality and safety by detecting defects or inconsistencies.

- Vision Systems : Use cameras and software to inspect bottles for fill levels, label placement, cap placement, and other quality parameters

- Checkweighers : Weigh each bottle to ensure it meets the specified weight range, rejecting bottles outside the range

- Case Packing Objective : To group bottles into cases for storage, transportation, and distribution.

- Case Erectors (Carton Formers) : Form flat cardboard into cases and close the bottom.

- Case Packers : Place bottles into cases. Spheretech offers Gantry type and Robotic case packers suitable for different speeds and configurations.

- Case Sealers : Seal cases using tape or glue to secure bottles during

- Palletizing Objective : To stack cases onto pallets for efficient handling and storage.

- Palletizers : Arrange cases on pallets in specified patterns. Options include robotic palletizers for flexible pattern configurations and conventional palletizers for high-speed applications.

- Pallet Wrappers : Wrap pallets with stretch film to stabilize the load and protect products during transportation.

- Control Systems and Software Objective : To integrate and manage the entire production line for optimal performance.

- PLC (Programmable Logic Controllers) : Control various machines and processes, ensuring synchronization and efficient operation.

- SCADA (Supervisory Control and Data Acquisition) : Monitor and control the production process, providing real-time data and analytics for decision-making.

- MES (Manufacturing Execution Systems) : Manage and track the production process, ensuring traceability and compliance with regulations.

- Line Layout : Designing an efficient layout to minimize bottlenecks and optimize flow.

- Flexibility : Ensuring the line can handle different bottle sizes, shapes, and product types.

- Safety and Compliance : Adhering to safety standards and regulatory requirements.

- Maintenance : Implementing a maintenance schedule to minimize downtime and extend equipment life.

- Training : Providing adequate training for operators and maintenance personnel.

A fully integrated production line from bottle feeding to case packing involves specialized equipment and control systems working in harmony. Each stage must be carefully planned and executed to ensure efficiency, accuracy, and product quality. Spheretech’s solutions provide a streamlined and cost-effective manufacturing process tailored to your specific needs.